When looking to revitalize industrial machinery, smart resource management is critical. Choosing used diesel engines is an economical option compared to new models, making financial and operational sense. These engines offer durability and a performance history, while controlling costs. Such strategic decisions maintain your operations’ continuity and effectiveness, plus they demonstrate a commitment to sustainability.

Maintain functionality with second-hand engines

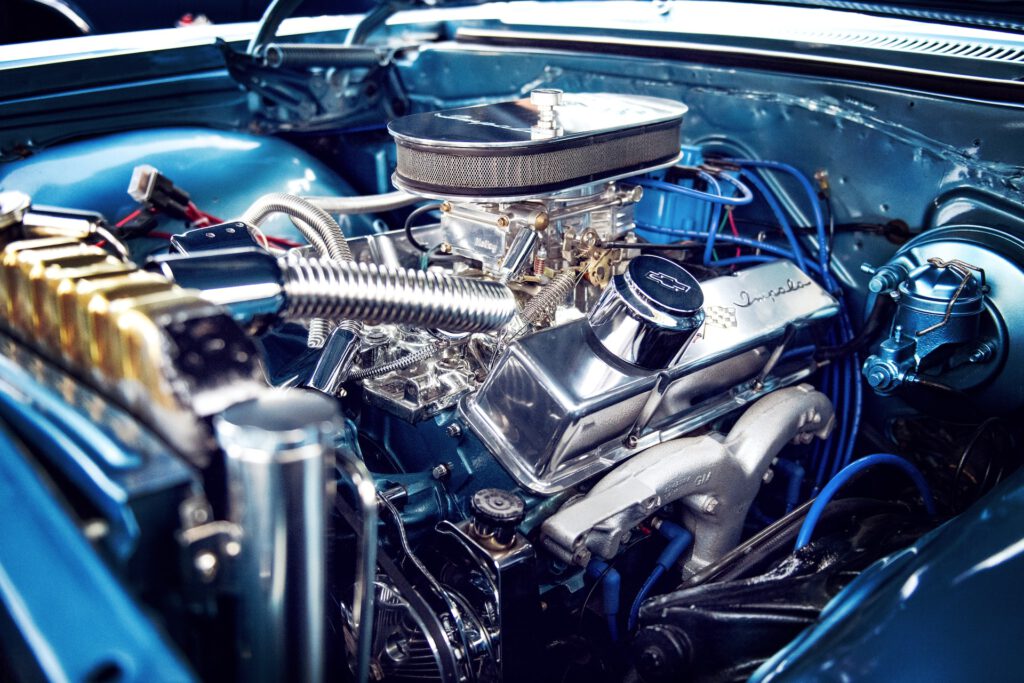

Ensuring that used engines are functional and long-lasting is paramount. Diesel engines are lauded for their robustness, often extending their service life past initial use. Refurbished diesel engines can match new ones in efficiency and reliability if properly maintained. Components like injectors, pistons, and crankshafts undergo strict inspections, upholding performance standards. Such diligence guarantees that the engine remains in good condition for demanding applications.

Tailor your machinery with available diesel engine parts

Adopting a pre-owned diesel engine allows for customization in your machinery setup, offering flexibility that new engines may lack. With a history of use, these engines come with a wider range of accessible parts in the aftermarket. This accessibility streamlines modifications for various needs. Customizing an engine for your specific machinery enhances operational efficiency and extends the life of your investment. Employing used diesel engines is a sign of intelligent financial foresight and an embrace of the circular economy. The cost benefits are clear, and this choice also promotes sustainability in your sector. With careful selection and expert guidance, the next used diesel engine you pick can turbocharge your business, helping to achieve production goals without the financial burden of new equipment. Adopting this practice revitalizes your machinery, enabling precise technical functionality, customization opportunities, and upholding performance sustainably.